PRODUCT CENTER

CONTACT US

If you are interested in cooperation, please contact us immediately, we will give you feedback as soon as possible!

Mobile

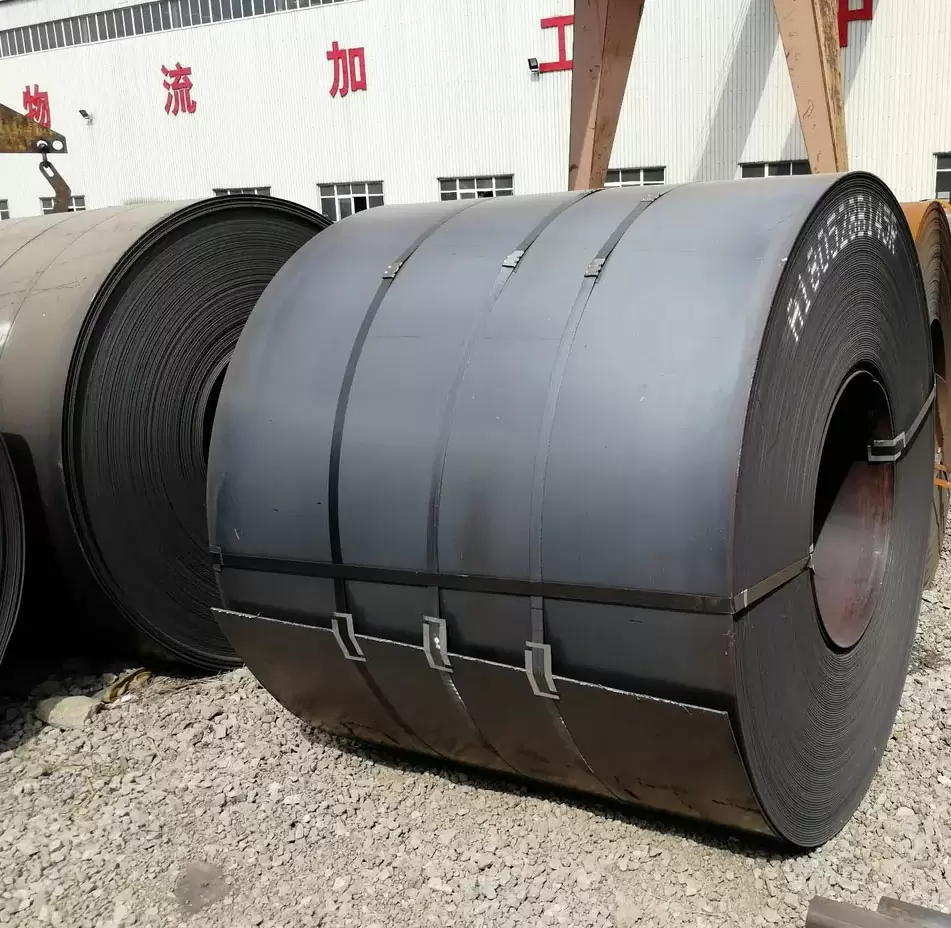

SGCH Steel coils are classified according to their professional uses, including oil drum plates, bulletproof plates, shipbuilding plates, automobile plates, construction plates, machining plates, etc.

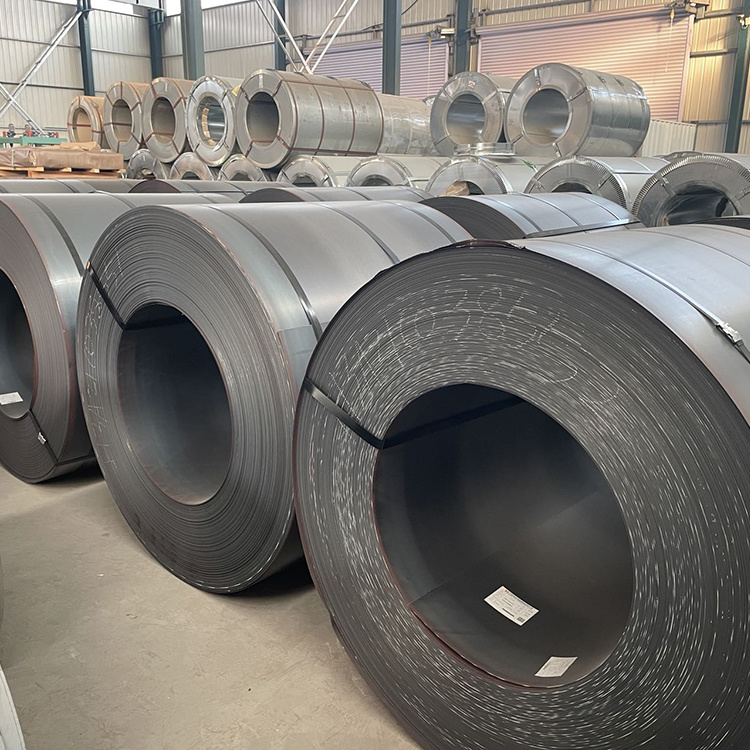

Specializing in the production and sales of carbon steel coils, factory direct sales, product grades and specifications are complete, and can certainly meet your various needs, welcome to consult.

SPCC is commonly used cold rolled carbon steel sheet and steel strip.Cold coil is made of hot rolled coil at room temperature and below the recrystallization temperature, including plate and coil, of which the sheet delivered is called steel plate, also known as box plate or plate; the long length and delivered in coil is called steel strip, also known as coil plate.

Cold rolled Non-Oriented silicon steel

Non oriented fully processed steels are iron-silicon alloys with varying silicon contents and have similar magnetic properties in all directions in the plan of the sheet. They are principally used for motors, generators, alternators, ballasts, small transformers and a variety of other electromagnetic applications.

Oriented silicon steel

Thickness: 0.18mm, 0.20mm or as required

Width: 1200/1250 or as required

Length: As required

Standard: AISI,ASTM,DIN,JIS,GB,JIS,etc.

PPGL Coil is a durable, colorful and economical building material. It is the abbreviation of color coated aluminum-zinc plated steel coil, which is based on aluminum-zinc plated steel coil. The aluminum-zinc coated steel is then continuously painted in coil form. Due to its heat resistance and corrosion resistance, it has become a material for various construction purposes, especially roofs and walls. Because it contains 55% aluminum, the corrosion resistance of PPGL coil is much better than that of PPGI, which can greatly extend the service life.

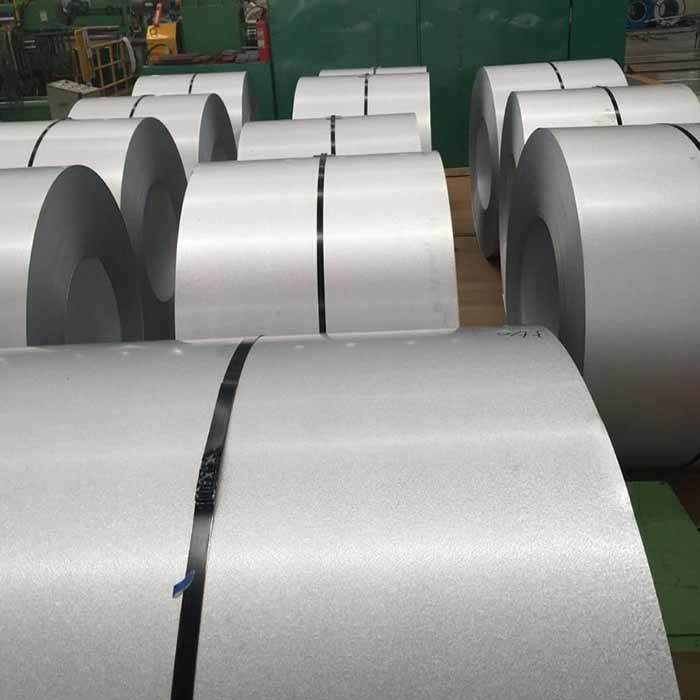

Hot Dipped Galvanized Steei Coil

Hot Dipped Galvanized Steei Coil is to make the molten metal react with the iron substrate to produce an alloy layer, so that the substrate and the coating are combined. Hot galvanizing is to pickle the steel and iron parts first. In order to remove the iron oxide on the surface of the steel and iron parts, after pickling, it is cleaned by ammonium chloride or zinc chloride aqueous solution or ammonium chloride and zinc chloride mixed aqueous solution tank, and then sent into the hot dip plating tank. Hot dip galvanized coil has the advantages of uniform coating, strong adhesion and long service life. Compared with other metal protection methods, the hot-dip galvanizing process has advantages in the protection characteristics of the combination of physical barrier and electrochemical protection of the coating, the bonding strength of the coating and the substrate, the compactness, durability, maintenance-free and economy of the coating, and its adaptability to the shape and size of the product.

Hot Dipped Galvalume Steel Coil

The surface of theGalvalume Coil is a unique smooth, flat and gorgeous star, and the basic color is silver white. The special coating structure makes it have excellent corrosion resistance. The normal service life of the Galvalume Coil can reach 25a, and the heat resistance is very good, which can be used in the high temperature environment of 315 ℃; The coating has good adhesion with the paint film, has good processing performance, and can be punched, sheared, welded, etc; The surface conductivity is very good.

SPCE is suitable for deep drawing grade steel.Cold rolled steel is our most common and commonly used cold rolled products.Its brand can be generally divided into: SPCC, SPCD, SPCE.

SPCE is suitable for deep drawing grade steel.